Datalogic - 5 Reasons Why Traceability has a Positive ROI

Thursday, December 12, 2019 4:43:39 PM America/New_York

In the first quarter of 2018, there were 72 consumer product recalls in the United States, more than five per week. Recalls are costly in time, money and brand reputation. While every manufacturer takes steps to avoid product recalls, they happen.

Manufacturers that are prepared for a recall will be much more likely to weather the detrimental effects to minimize cost, ensure customer safety, handle legal or regulatory consequences, and protect their brand. But you can prepare your company for the worst by implementing traceability technology that provides timely, relevant data to help mitigate the impact of a recall. Demand is increasing for track and trace solutions with the market projected to reach $4.21 billion by 2024, up from $2.16 billion in 2019 at a CAGR of 14.2 percent.

This demand is driven by:

- Stringent regulations and standards for the implementation of serialization

- The increasing focus of manufacturers on brand protection

- The increasing number of packaging-related product recalls

- High growth in the generic and OTC markets

- The growing medical device industry

What is Traceability?

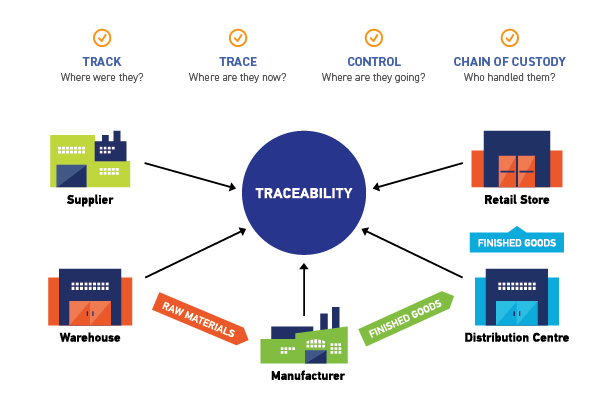

Traceability is the capability to trace something or the ability to verify the history, location or application of an item through documented, recorded identification. Traceability helps improve visibility across the supply chain, leading to better control

and communication in the event of a product recall. When manufacturers can see where potentially contaminated product is in the delivery process, they have a crucial advantage in getting ahead of the problem. The faster a manufacturer can identify where impacted product has been delivered, the quicker the company can take action.

For discrete manufacturers: Traceability is the ability to track and trace each component of each product, from

suppliers and manufacturers through assembly and final delivery to customers.

For food and other process manufacturers: Traceability is the ability to trace each ingredient of a product from

“farm to fork” through the creation of a batch genealogy.

Traceability goes beyond the ability to read barcodes. Traceability captures the movement of a component or

product throughout its lifecycle.

Why Do You Need It?

The Potential for Recalls is Driving the Need

When a product is recalled, significant time, money and manpower are spent in diagnosing the problem and retrieving the products from the marketplace.

|

In 2018, an E. coli outbreak in Romaine lettuce resulted in 150 consumers falling ill. But the problem could not be traced to the region where the lettuce was grown, so it was impossible to pinpoint the source or reason for the contamination. |

| The National Highway Traffic Safety Administration reports that automotive recalls have been increasing in frequency and intensity. In 2017, a staggering 3.1 vehicles were recalled for each vehicle sold. The scale of automotive recalls has also increased. Before 2015, the average recall rarely exceeded 30,000 vehicles. But in 2016, volumes peaked at 90,000 vehicles per incident and 46,000 units in 2017. |  |

|

In USDA- and FDA-regulated markets, there have been a slightly higher number of recall incidents in the beginning months of 2019 versus 2018. Mispackaging is identified as one of the primary recall issues, involving packaging a finished product into the wrong container. Other issues prompting recalls include package labeling errors where potentially allergenic ingredients are not disclosed. Also, consumer reports of foreign materials in finished products have prompted recalls. |

5 Reasons why Traceability has a Positive ROI

Traceability helps pinpoint the problem, allowing companies to narrow the scope of the recall to the source of the problem in order to avoid a recall of all manufactured products. Traceability gives companies a powerful tool to minimize the impact of recalls, and is critical to minimizing costs and the potential negative impact to customer and distribution channel loyalty.

1. Brand Protection

A positive brand reputation takes years to develop. But brand damage can happen within days and persist for years, and possibly become permanent. With that in mind, it’s worth considering how a recall can significantly erode the value of years’ of customer satisfaction.

2. Consumer Safety

Most industries have product safety standards that must be followed. When a product defect puts customer safety at risk, the manufacturer must spend resources to respond.

Examples of consumer safety protections include:

- Produce industry products must be free of contaminants such as E.coli.

- Automotive industry products must be free of defects that affect consumer safety

- Healthcare industry products such as medication and devices must be free of defects that can cause harm to patients.

3. Compliance

The FDA and CDC strongly encourage the supply chain to adopt traceability best practices and state-of-the-art technology to allow quick access to key data elements.

Big retailers like Walmart are asking producers to embed key information into product packaging, including:

- Lot Number

- Harvest Date

- Best Before

- Specfic Growing Area

4. Cost Mitigation

DIRECT COSTS

The direct costs associated with recalls include removing products from the marketplace, investing in media buys to reach out to consumers, and retrieving, destroying or fixing affected products. Customers may require reimbursement or credit, and warranty repair costs can soar. Costs to the automotive industry in 2018 for warranty claims payments was $7.79 billion, up from $747 million, or 11 percent, from 2017.

Finally, legal fees and fines for regulated businesses can add negative impact to the bottom line. For example, fines for produce contamination range from $4,000 to $1.9 million.

INDIRECT COSTS

The impact to the company’s reputation and brand can be enormous. Damage to the brand is costly. To recover lost market share, companies will be motivated to spend more on marketing advertising.

Companies can lose market share in a product category or across the product line. In the E. coli outbreak, sales of Romaine lettuce plunged 45 percent due to loss of consumer trust, and the sale price of lettuce dropped 60 percent.

And, costs can escalate. A recall may result in increased regulatory costs, increased product liability insurance costs and increases in testing and sampling costs.

| Track-and-trace solutions not only help manage recalls, they also help avoid unnecessarily recalling unaffected products. If you know the source, you only need to recall products associated with the source. The FDA estimates that 400 recalls per year could be prevented if manufacturers had better control practices. |

5. Product Optimization

While traceability is helpful for responding to recalls, it can also help optimize the production line and manufacturing timelines. By collecting data at each process step, from receiving raw materials all the way through distribution, a traceability solution can help companies better balance supply and demand.

How is it Implemented?

Successful implementation of traceability involves the right mix of technologies that work together to track and trace products and components.

|

LASER MARKING Selecting a proven laser marking solution is vital for applications requiring reliable Direct Part Marking (DPM) in manufacturing, including automotive, precision mechanics, industrial electronics, healthcare manufacturing and other industries. For traceability, laser marking solutions mark serial numbers, and lot and batch numbers with 1D and 2D barcodes and human readable codes. Laser marking solutions should be able to mark in-line with markings that are permanenet, durable and counterfeit proof. They should also be fast and easy to integreate with vision systems. |

|

SAFETY LASER SCANNER Safety laser scanners guide products along the manufacturing line to avoid collisions by slowing the line down or stopping when in the prescence of operators or obstacles. |

|

STATIONARY READERS Your traceability solution should include stationary readers to confirm that labels have been applied and are readable. It's ideal to deploy one reader that can read all materials including paper, packaging, plastics, and metals, so there's no need to carry mulitple lighting options. |

|

HANDHELD READERS Demanding application require ruggedized, cordless, handheld scanners that are versatile, easy to use and feature outstanding radio range for forklift picking, bin picking, order fullfillment, and shipping and receiving. |

|

VISION SYSTEMS Machine vision functionalities should include an ultra-compact smart camera to inspect the "human readable" code next ot the barcode (direct part marks). The camera aids in patter identification, flexible packaging such as pallets with different products, and imaging archiving. |

What is the ROI?

Traceability technologies and processes ensure product quality standards are met and give real-time information about production and equipment. Companies can track production information back to the exact date, time, supplier components, operator, and machines used.

Business Benefits

Traceability is an automated process that generates reliable data to improve processes and respond to a product recall. It significantly reduces errors because producers know where everything came from and where it’s going.

The real-time information provided by traceability technology helps improve product quality and improve customer satisfaction and safety. Traceability technology helps companies meet or exceed compliance mandates. And, this technology helps simplify supply chain management ensuring companies always have what they need when they need it, without the need to invest in more than is required.

Traceability enables manufacturers to accurately analyze the root cause of a product or part failure to recover warranty costs from liable suppliers.

Traceability can help improve quality issues before they occur, and allow for swift action should an error occur. Traceability can reduce quality costs 10 to 15 percent, leading to lower warranty claim costs.

Protect Your Brand and Your Profits

Product recalls are expensive, time-intensive, and can take a toll on your company’s reputation. It can take years for a brand to recover from a product recall.

Manufactures that are proactive in responding to recalls can minimize safety effects for consumers. Traceability technology helps manufacturers get in front of the problem early by providing valuable information on the source of a problem. Traceability helps narrow the focus of a recall to contain costs and brand damage.

Go beyond the barcode to implement an end-to-end traceability solution that crosses each stage of the manufacturing line.

Contact Scott Equipment Company to learn how Datalogic can help you potect your brand and your customers